Table Of Content

The 1,407-square-foot house — complete with three bedrooms, two baths and a two-car garage in Riverhead, New York — listed as “the world’s first 3D-printed home for sale” for $299,999 on Zillow.com. Aside from time and money, several other reasons explain additive manufacturing’s disruption to the construction market. Many see this type of low-waste, computerized homebuilding delivered from an industrial-scale printer as a way to shelter unhoused communities and a gateway to sustainable, biodegradable housing solutions.

Floorplan For A One-Bedroom 3D Printed House

Their latest model, the CyBe G, is gantry-based with a four-column, three-beam configuration, ideal for affordable housing construction. At 500 mm/s, the CyBe G boasts of one of the fastest printing speeds for 3D printed house construction. Then in 2019, Apis Cor made headlines again when they built the largest 3D printed house in the world, a huge building in Dubai to be used for administrative purposes. Having built houses in Russia’s tough winter climate as well as hot Dubai, Apis Cor have proven they can create durable 3D printed houses anywhere. Meanwhile, another ICON project, House Zero, has been making headlines for pushing the boundaries in the 3D printed home construction industry. Located in East Austin, House Zero is a 3-bedroom house that was constructed with significantly less time, cost, and waste than traditional building methods.

How Much Does It Cost To Build A 3D Printed House?

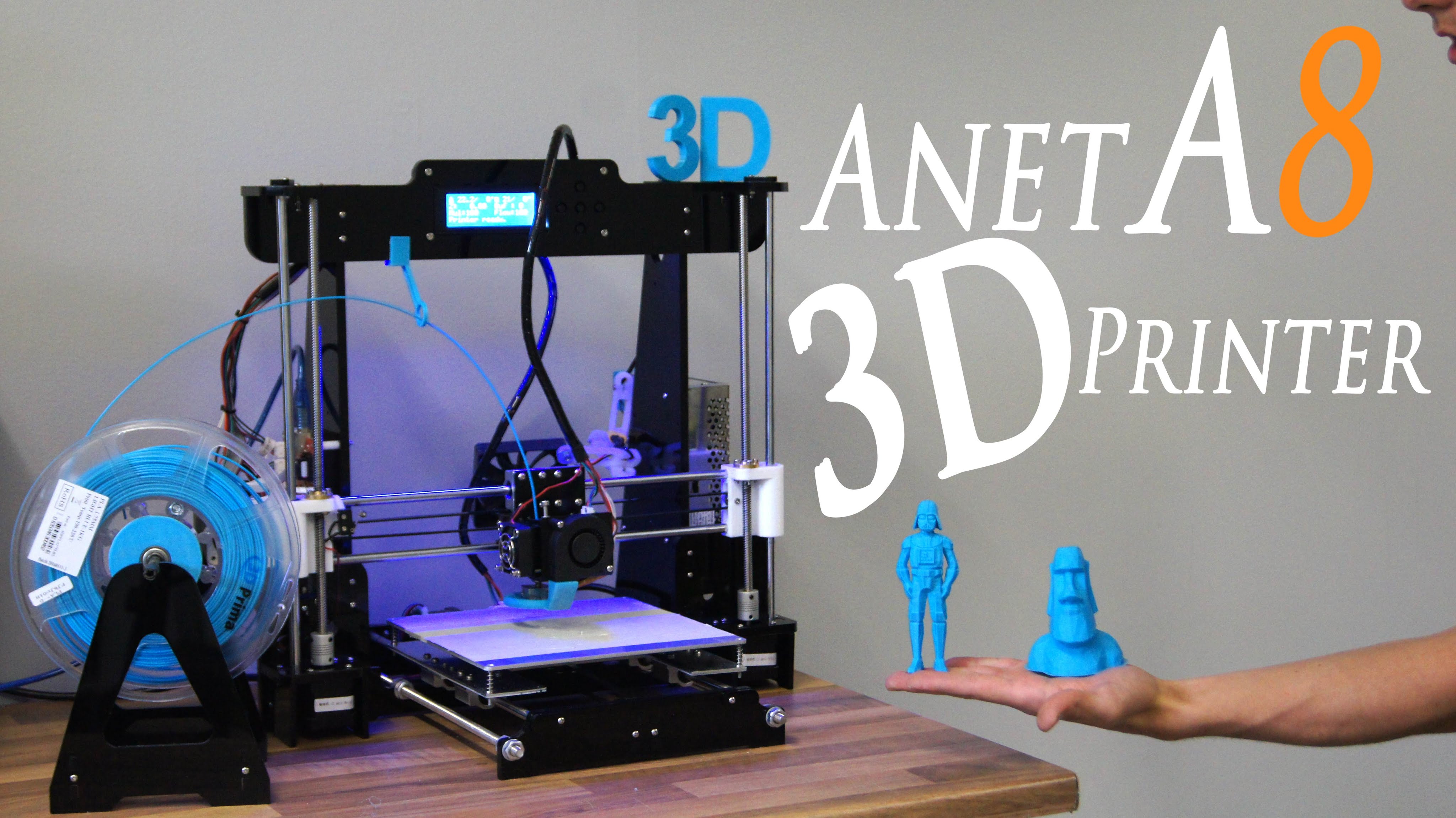

Building a 3D printed tiny house can be more cost effective, time efficient, and just as structurally durable as a traditional home. A construction 3D printer is a machine that can build houses by depositing a material (concrete for example) layer by layer. Concrete 3D printing – a.k.a. “Construction 4.0” – is a similar 3D printing technology to the one that FFF 3D printers use. Paste-type material, in this case, concrete or earth materials, is pushed through a nozzle in layers to print buildings in 3D. These four Austin, Texas properties by construction 3D-printing company ICON feature open-floor plans, minimal architectural aesthetics and private yards. Varying in size, these residences feature two to four bedrooms and range from 1,000 to 2,000-square-foot homes.

The most Exciting 3D Printed Houses & 3D Printed Buildings

Video: Europe's biggest 3D-printed building rises in just 140 hours - New Atlas

Video: Europe's biggest 3D-printed building rises in just 140 hours.

Posted: Wed, 06 Mar 2024 08:00:00 GMT [source]

Another material gaining popularity is bioplastics, derived from renewable sources such as cornstarch or algae. By using this technology, housing modules can be built within 200 hours while consuming an average of six kilowatts of energy and reducing typical construction waste. While this may become possible in the future, it should be left in the hands of the experts for now. I want to reiterate here the importance of refraining from building a 3D printed tiny home on your own. I tend to tell my friends that DIY building is for anyone, and you don’t have to have a ton of experience to be successful. This unique building was completed by a consortium of companies in early 2019 and is based in Switzerland.

Our homes

Joining forces this time with developer 3Strands, ICON has used its Vulcan technology to construct four multi-story buildings in East Austin ranging from 1,000 to 2,000 square feet, featuring modern open plans and timeless interiors. But just because there’s a new printer on the block doesn’t mean UMaine’s previous record-holder is obsolete. Designers created FoF 1.0 to print in tandem with MasterPrint, with the two machines even capable of working together on the same building components.

Probably the most famous and viral 3D printed house build, this interestingly shaped house was built back in 2017 in just one day – while it snowed! According to the team the house cost just over $10,000 to build, including the furnishings with windows and doors, though we will discuss why these figures may not tell the full story further on in this article. Perhaps the most exciting part of this build however is the architecture – the house was built to curve around environmentally-protected trees.

Standardized Sustainable Homes, Enhancing Canada's Housing Landscape

Reinforced by steel, the walls are printed within 10 days with a proprietary material ICON refers to as Lavacrete – a cement-like substance that is air-tight while additionally providing increased insulation. Without a doubt, this process offers significant potential to increase efficiency and productivity. Not only does it offer a high degree of planning reliability from the start, lowering chances of design errors and worker injuries – but it also requires low coordination and monitoring efforts. Construction time reduces drastically with this, which also translates to fewer costs.

Could 3D-printed homes help solve the affordable-housing crisis? - Marketplace

Could 3D-printed homes help solve the affordable-housing crisis?.

Posted: Mon, 04 Dec 2023 08:00:00 GMT [source]

A document published by COBOD, a Danish company that is a global leader in 3D printing solutions for the construction industry, warns consumers by taking stock of what 3D construction is really like today. For example, it mentions the company Winsun, which claims to have built 10 3D buildings in 10 days. In fact, they assembled 10 buildings in 10 days, from 3D printed components produced in a factory long before.

3D printed tiny houses are fully livable homes that are built layer by layer with industrial-grade, 3D printing technology. A 3D printed house is created with a cone shaped printer that follows the builder and designer’s instructional code. The build and design team sets the concrete thickness, wall dimensions, and printing pace through their computer. Nestled away in a gated, hilltop community in southern California, Ehrlich Yanai Rhee Chaney Architects have built a 20-home, net-zero development that aims to consume as much energy as it generates.

The Dutch house 3D printer company has two construction 3D printer models, the CyBe RC 3Dp, and CyBe R 3Dp, able to print structures quickly at up to 200mm/s. They also use patented materials based on concrete mix, and claim they can fully construct houses for under $100,000. Back here on earth, ICON has extended its business horizon to include housing philanthropy. Village, the company 3D printed six 400-square foot homes for people that have gone through chronic homelessness. But Dagher says the notable difference between other 3D-printed homes and the University of Maine’s prototype is the material from which they’re built. The Texas neighborhood under construction is being printed with lavacrete, a cement-based mix.

In this case, "extruding" refers specifically to the method of pushing the printing material (usually a thermoplastic filament) through a heated nozzle, where it melts and is deposited onto a build platform to create the desired 3D shape. Through state-of-the-art 3D printing technology, we’re pioneering innovative, stronger, faster and more cost-effective building solutions that are environmentally responsible. One of the most exciting possibilities of 3D-printed architecture is that it could revolutionize affordable housing. Portugal's Havelar shows this may soon be within reach with its inaugural 3D-printed home, which took just 18 hours to print. They sell their very own concrete construction 3D printer, the BEM Pro 2, which can operate even in hot and harsh climates, making it great for 3D printing houses near the equator.

Our goal is to become experts on a wide variety of different types of printers, materials, and methods in order to expand our understanding and gain insightful knowledge of the best practices for the future of this industry. Alquist is the only 3DCP company that has the knowledge to work directly with local city officials, passcode and permitting, and successfully print a home using multiple printers and/or materials. Mense-Korte’s 3D-printed house, located in Beckum, Germany, is the first in the world to become fully certified by a national government’s building regulation. This modernist, three-bedroom, three-bathroom home measures 1,722 square feet of living space, complete with a sophisticated interior and smart-home technology.

No comments:

Post a Comment